Precautions when wiring the film panel

The thin-film panel circuit is limited by parameters such as current, resistance, withstand voltage, insulation, and life. In order to ensure the function of the circuit, we must first ensure the quality of the silk-screen silver paste circuit. Since the selected thick wire mesh has serrated edges, it should be fully considered and paid attention to in the production of the membrane switch version, and it should be corrected and avoided in the production. According to practical experience, the following points should be paid attention to in the manufacture of thin-film panel circuits:

1. The dry sieve should be checked for pinholes and air bubbles and repaired. After re-drying, a second exposure must be carried out to make the contact of the hard plate photosensitive adhesive completely firm, thereby improving the printing durability of the screen.

2. Select a larger screen frame and tighten the screen plate. The grid is large, the deformation is small, and the operation is convenient. The screen frame is very tight, which is conducive to the sensitive separation of printing material and screen, and is more conducive to the shunting of high-viscosity silver paste.

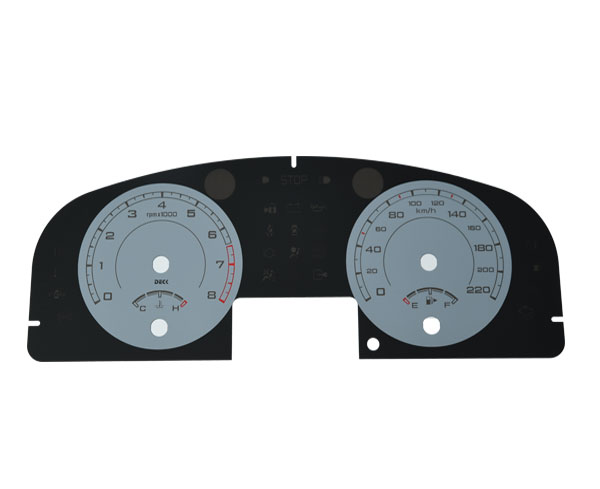

Film panel

3. When printing the film panel, the screen is closely related to the film. It should not be too long, otherwise it will be difficult to develop, and it should not be too short, otherwise it cannot be printed and the lines will become thicker. Then put the dry stencil on the top of the pool, rinse it with low water JK, and let it dry after the stencil photosensitive adhesive is developed evenly and fully.

4. When applying glue by hand, the glue surface should be flat. Four applications are generally recommended, but there are special cases, depending on the thickness of the photoresist. When applying glue for the first time, repeatedly scrape both sides of the screen evenly to make the photosensitive glue evenly fill the screen. Then dry in the oven (note each time you scrape: make sure it's dry). Apply a second and third coat of glue to the screen printed side and let dry. Apply glue a fourth time, then scrape once on the surface of the spatula.