What are the methods of membrane switch proofing

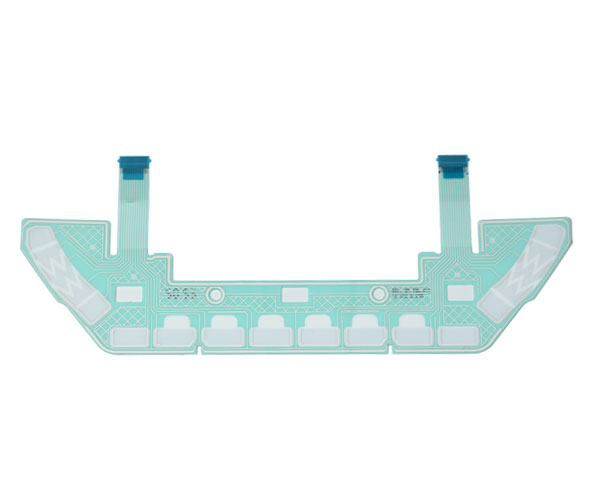

Membrane switches are operating systems that integrate key functions, indicating elements and instrument panels. It consists of a panel, an upper circuit, an isolation layer and a lower circuit. It has the characteristics of strict structure, beautiful appearance, good sealing performance, moisture resistance and long service life, and is widely used in electronic communication, electronic measuring instruments, industrial control, automobile industry, smart toys, household appliances and other fields. Membrane switch proofing is the connection process between pre-press production and printing, which allows users to predict the effect of membrane switches before mass production, provides a standard for the entire membrane switch production process, and provides a strong guarantee for improving quality. The following are two switch proofing methods for membrane switches; 1. Soft proofing It is undoubtedly a convenient, fast and cheap proofing method to realize soft proofing on a color display. It requires a high-precision color display, and it requires a color-calibrated display.

2. Traditional proofing

Need to output film and silk screen, and then complete the proofing on the screen printing machine. The production process of the traditional proofing version is the same as that of the production version. The same file data is used for proofing and mass production, and potential problems such as cracks, colors and font patterns can be found. Membrane switch samples have high technical content and require professional technicians to make accurate samples. In addition, the labor intensity is high, the process is many, the cost is high, and the sample production cycle is long.

The following are the two calibration methods for membrane switches. We can choose products according to our own needs. If there is anything unclear in this process, you can call our staff for detailed consultation.