The secret of membrane switch principle

The emergence of an industrial technology is often the result of the hard work of many people or even several generations. The purpose of continuous research and deliberation is to bring people a more comfortable and convenient life. The birth of new industrial products is to be more subtly. They are integrated into people's daily life. You may not fully know these products, but you will definitely encounter them in life. If you know their principles, it is very helpful to solve some small problems. Here is a new type of industrial product , Xiaobian takes you to understand its principle. ?? Membrane switch is an operating system that integrates key functions, indicating components, and instrument panels. It consists of four parts: panel, upper circuit, isolation layer and lower circuit. It is a light touch-on normally open switch. Under normal circumstances, the upper and lower contacts of the membrane switch are disconnected. When the membrane switch is pressed, the contacts of the upper circuit are deformed downward, and are in contact with the pole plate of the lower circuit. After the finger is released, the contacts of the upper circuit bounce back, the circuit is disconnected, and the circuit triggers a signal. The membrane switch has strict structure, beautiful appearance and good sealing performance. It has the characteristics of moisture resistance and long service life. Widely used in electronic communication, electronic measuring instruments, industrial control, medical equipment, automobile industry, smart toys, household appliances and other fields.

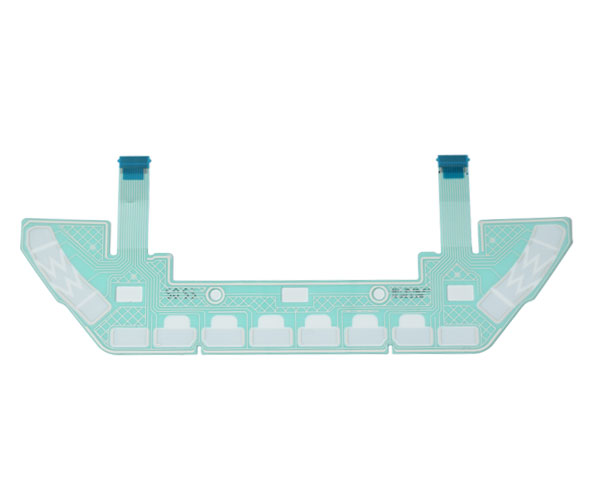

A multi-layer structure (flat) type (non-locking) key switch composed of a certain elastic insulating material layer, often called a membrane switch. It has the characteristics of beautiful appearance, long service life, simple structure, convenient installation, good use feeling and small occupied area. The market for tact switches. It has a huge share in the market.

The structure of the membrane switch: faceplate, faceplate adhesive, upper circuit, isolation layer (wire key, lower circuit of the surface key and adhesive layer. The mask layer, the upper circuit layer and the lower circuit layer are transparent films. The main materials used are It is PC, PET, PVC. The material of the mask adhesive, isolation layer and adhesive layer is double-sided adhesive (commonly known as sandwich button trigger principle: when the mask is not pressed, the isolation layer isolates the upper and lower lines, and when the mask layer is pressed When pressed, the upper line is pressed together and overlapped with the lower line, so that the line is turned on. The connected line sends a signal to the external connection instrument (substrate) to realize its corresponding function. The surface of the substrate requires smooth, Rust-free and cleaned with alcohol or gasoline before mounting.

The life of the membrane switch can generally reach more than 10,000 times. The action of the switch is only realized by the vertical direction of the elastic film. Although the elastic film has undergone a million times of creep, the amplitude of the creep is very small. Only 0.1-0.3MM, coupled with the rationality of material selection, so the membrane material can withstand a long life of more than one million times without deformation, which determines the durability of the membrane switch.

Its sealing requirements are strict, but after the production is completed, the switch contacts will not be eroded by harmful gases, not easy to be oxidized, waterproof, dustproof and oilproof, suitable for various harsh environments. Membrane switches are designed to be arranged to form a membrane keyboard, with a high density and a sealed sheet structure composed of multiple layers of membranes. The connection lines and lead-out lines between all switches are completed by screen printing at one time. The total thickness is 1-3MM. Greatly reduced size. Lightweight and reliable quality. Compared with the traditional mechanical switch, its installation is convenient and simple. Just stick it lightly, peel off the adhesive tape, then fix the surface of the whole machine, insert the lead outlet into the socket of the rear circuit of the whole machine, and the circuit can be connected in an instant, and the use of the whole product can be completed. In the design of the shape, according to the user's design concept, the color pattern can reflect the individuality, and the decorative effect can reflect the beauty of the material and the production process.