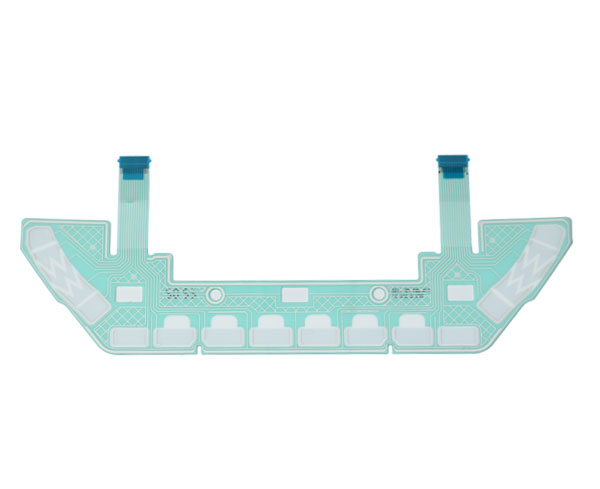

Membrane panel switch characteristics and waterproof, in life, we know that the ordinary membrane switch has excellent waterproof performance, in the relevant oil, dust, humidity and other aspects are very good, can be used in a variety of environments. Do Not Know Waterproof, oil-proof, moistureproof film switch has what characteristic, and do not have what difference of this characteristic film switch, why can have such outstanding effect. What are the characteristics of waterproof membrane switch, material in the rain before normal operation? The main characteristic of waterproof membrane switch is that the conductor road is coated with waterproof insulating layer, so that the conductor road and the pressure-sensitive adhesive layer do not directly contact. In addition, in the range of 5m/m, the upper and lower loop surfaces are separated by non-porous conductors, and the inter-layer ventilation holes are not connected with the outside world. Then, the situation that the moisture absorption of the adhesive layer leads to the decrease of the insulation resistance of the circuit is improved, and the water immersion condition inside the circuit is improved. Therefore, the utility model has the advantages of water-proof, moisture-proof, etc. . Therefore, the waterproof membrane switch does not have the above requirements, also does not have the waterproof function. The waterproof membrane switch is: uses the high performance waterproof material, causes the product to use under 95% moist environment. Do not worry about rain water, can be used in harsh environment.SWITCH STRUCTURE OF MEMBRANE PANEL: 1. PLANAR NON-CONTACT MEMBRANE SWITCH: Long Service Life, non-contact; . Film CONVEX TACTILE: tactile prominent, but relatively short service life;. CONVEX frame without touch: surface beautiful, three-dimensional feeling strong, but no touch;. CONVEX frame tactile type: surface beauty, three-dimensional feeling strong, strong touch;. Panel contact: when the design is not correct, there are two simple phenomena, but the panel damage, electrical functions also exist;. Metal Shrapnel type: feel good, shrapnel not only play the role of touch, but also play the role of lines; metal shrapnel is mainly used for printed circuit boards and other hard membrane switch, give full play to the shrapnel permeability, resilience and feel. The application of shrapnel in flexible membrane switch is mainly to provide tactile response (i. e. hand feeling) which is not usually needed. The disadvantage is that the gap between the metal shrapnel and the switch contact causes the shrapnel to be out of sync with the switch. That is, when the shrapnel is activated, the switch contacts may not be activated at the same time. Furthermore, in FPC, the action of the shrapnel often exceeds the horizontal plane at the bottom. When the operating force is too large, easy to make the shrapnel in the opposite direction deformation, unable to respond, commonly known as death. In fact, in FPC, the feeling of the keys can be guaranteed by the collision of the circuit layers. Our factory has advanced drum packaging equipment and technology, to ensure that the keys feel even, feel good.Luminous body type: must open bottom plastic mold; A) the led line is on the same level as the lower line: simple structure, but the led light window is prominent, otherwise the led light will cover the top of the panel; suitable for low-height small led lights or led light less occasion; b) The led light line and the lower line of different levels: the structure is messy, but the led light window must be suitable for two-color led lights or led light more occasion; need to open the mold and bottom mold; 8. Folding type: This type prevents jumpers and allows the conductive surface to be lowered without the GROMMET. The defect in this structure is only on the fold line. Figure 9. Inner Frame Waterproof: The outer frame is closed frame, no connection, protect the inner frame, prevent the water vapor from the outlet slot into the outer Shell. Requirements and standards for raw materials of thin film panels. Raw data is an important step in the production of any product, responsible for the appearance and protection of the product. For Shanghai film panel, the original data should at least have good chemical resistance: that is, most alcohols, ethers, mineral oils and other common chemicals should have some tolerance. Elasticity: The panels are thin and have a degree of back weakness. At the same time, the elastic deformation should be small, can be judged by the elongation of the data. In general, large elongation, elastic deformation, poor resilience, beautiful appearance: refers to the production of the surface film appearance smooth, gloss consistent, no mechanical damage, scratches, inclusions, spots and other appearance defects; Good Weather Resistance: The surface layer is the membrane switch, exposed to the natural environment. In a certain natural environment, the panel data can not be deformed, cracked, aged, discolored, good dimensional stability: In a certain temperature range (- 40 ° C ~ 55 ° C) , the panel film size can not change significantly. According to the above requirements, the films commonly used in Shanghai thin film board usually include polyester film, polyvinyl chloride film, Polyester Film and Polyurethane Film.